ABOUT US

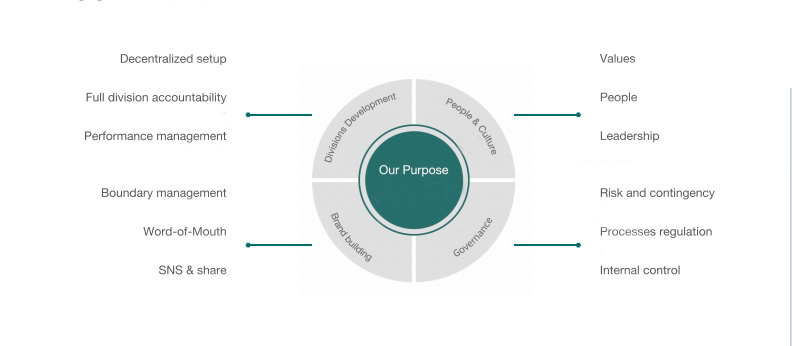

ZTELEC’s purpose is to create quality products and provide solutions to create value for customers.

ZTELEC’s purpose is to create quality products and provide solutions to create value for customers.

Founded in 1958,Henan ZhongTian Electric Equipment Group (hereinafter referred to as Ztelec Group)was formerly owned by the Ministry of Light Industry.Ztelec Group adheres to the core value concept of "Vision,Innovation and Responsibility",takes"Power the world with green and reliability"as its own responsibility.Focusing on production and manufacturing over 65 years,the group has developed into an integrated group company specializing in four industries:Electric equipment,Composite materials,Enameled copper wires and Photovoltaic energy.The Ztelec Group company is represented by 7 manufacturing bases across 5 cities (Xuchang,Zhengzhou,Guiyang,Chengdu,Dongguan)in China,with more than 1500 employees word wide.

Ztelec Group focuses on the manufacturing of high-voltage variable frequency control equipment,complete sets of equipment for medium and low voltage power transmission and distribution networks,smart grids,ESS pre-installed energy storage stations (ESS),and distributed power generation systems.Ztelec owns1 national postdoctoral research station,2 provincial technology centers,closely cooperates with National Advanced Materials Laboratory of Beihang University and Institute of Plasma of Chinese Academy of Sciences,promoting intelligent manufacturing level and digitization transformation.Ztelec is a Chinese enterprise committed to the development of globalization,committed to promoting an open technology and partner ecosystem,and actively practicing the common values of meaning,inclusiveness and empowerment.

It is our responsibility to help customers create maximum value by providinghighlyreliableandappropriateproducts.Adhering to innovationbased oncustomerneeds,embracingchanges,weacceptchallengestogether withourcustomers.

ZtelecGroup is committed to global exhibition layout and regards quality as life. Our electrical products such as transformers and switchgear have passed CE, UL/CUL, CNAS certifications, etc. We manufacture our products with a spirit of craftsmanship. And our product quality meets international certification standards, ensuring that the products you receive not only meet the requirements, but also have excellent performance.

We comply with various standards, including IEEE/ANSI, CSA, DOE, AS/NZS, and IEC. We carefully design transformers to ensure they fully meet your regulatory and operational needs.

We deliver on time without compromising quality. For standard transformers our production time is 5-6 weeks and for custom solutions we deliver within 6-8 weeks. This fast turnaround is our commitment to ensure your project is completed on time.

The continuous improvement of economics and environment in our community and the promotion life quality of our staff and their families are the sustained aims of Ztelec.

In order to achieve these aims,Ztelec has made great efforts on the balance among economic developments and environment protection,including how to design and manufacture product;how to refine product and service provided;how to cooperate with local suppliers and to evaluate risks and opportunities;how to fulfill its responsibility and so on.

+Our culture

+Customer First +Embrace Changes +Devotion +Care with Respect

Make quick response tothecustomer'sspecial requirements on environment,appearance,efficiency, delivery time,transportation,special quality andothers, providepersonalizeddesign,andshorten the delivery cycletime

control concept from warehousing raw material control to finished products inspection,focus on customer's experiences and core needs,and provide products and services that exceed customers'expectation.

1.Vacuum casting system 2.Cut-to-length line for core sheets 3.Vacuum drying equipment 4.Winding equipmen

Introduced lean production concept,we established 50 lean improvement quality criteria (LS).Each process is provided with operation instructions and standardized operations criteria to implement the production plan,through timely management (SIM)to improve communication efficiency and continuously shorten delivery time.TPS with core of production process management (MPS)has gradually been developed by connecting sales, materials,planning,supply SO on

Copyright © 2022 ZTelec Group. All rights reserved.