500 KVA Dry Type Amorphous Alloy Transformer

03-11 2025 | By:

Dry Transformer Manufacturer

Primary Voltage:11KV

Secondary Voltage:0.4KV

Power Rating: 500 KVA

Connection Type: Dyn11/Yyno or others

Transformer Type: Dry Type Transformer

Standards: ANSI/IEEE, CSA/CAN, DOE

About 500 KVA Dry Type Amorphous Alloy Transformer

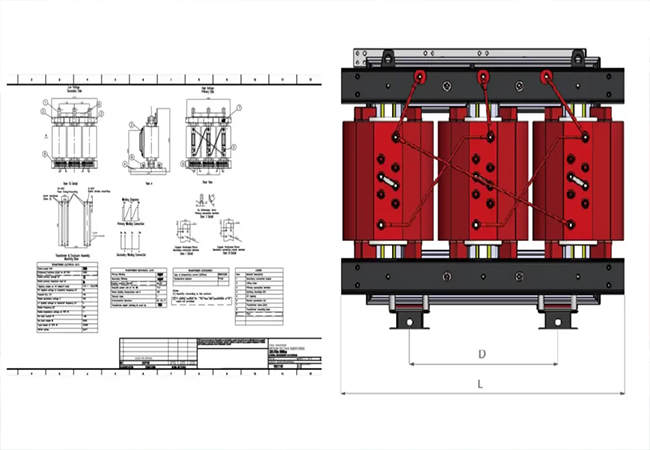

Epoxy Resin Transformer

In 2024, we received a significant order from our esteemed client in Philippines for 2 units of 500 KVA Dry Type Amorphous Alloy Transformers. Tailored to their specifications, these transformers boast a primary voltage of 11KV, secondary voltage of 0.4KV, and a capacity of 500 KVA, employing a delta connection method. Our choice of epoxy resin casting and amorphous alloy material ensures their high efficiency, energy-saving capability, stability, reliability, and environmental friendliness. Leveraging resin casting technology and internal foil winding, we achieve outstanding insulation properties and environmental sustainability while guaranteeing excellent dielectric performance and short-circuit withstand capability, rendering them suitable for both distribution and specialized applications.

ZTELECGROUP offers customizable Dry Type Amorphous Alloy Transformers ranging from 100KVA to 2500KVA, with voltage levels up to 35KV. Contact us to learn more about our Dry Type Amorphous Alloy Transformers and explore how they can meet your specific requirements!

What is 500 KVA Dry Type Amorphous Alloy Transformer

The SCB 500KVA Dry Type Amorphous Alloy Transformer is a contemporary energy-efficient dry-type transformer. Its no-load loss is reduced by 75% compared to GB/T10228 Table 4, and load loss is reduced by 15%. The transformer features maintenance-free operation, resistance to humidity and heat, fire resistance, explosion-proof design, low partial discharge, and strong heat dissipation capability.

ztelecgruop transformer

Anywhere conventional dry-type transformers are currently used, including airports, railway stations, urban metros, high-rise buildings, and power plants, can be replaced with amorphous alloy dry-type transformers. These transformers can be placed at the load center, meeting the needs of modern high-density urban development.

The high-voltage coil is wound with H-grade high-strength enameled wire, while the low-voltage coil is wound with copper foil and vacuum impregnated. The core is made from amorphous alloy strips, featuring a rectangular cross-section, a three-frame three-column structure, peripheral passage for zero-sequence magnetic flux, and robust short-circuit resistance capability.

500 KVA Dry Type Amorphous Alloy Transformer Main Structure

- Core: The core adopts imported cold-rolled silicon steel sheets with a three-step full-slant joint structure. The core column is bound with F-grade non-weft banding. The core surface is encapsulated with epoxy resin, reducing no-load losses, no-load current, and iron sheet noise. The brackets and tight turn components undergo special surface treatment, further improving the appearance quality of the product.

- Temperature Control System and Air Cooling System: Utilizes a cross-flow top-blown cooling fan, characterized by low noise, high air pressure, and aesthetic appearance, enhancing the transformer’s overload capacity. The temperature control employs an intelligent temperature controller, improving the transformer’s operational performance.

- Protective Enclosure and Busbars: The protective enclosure provides further safety protection for the transformer, with protection levels such as IP20 and IP23. Enclosure materials include aluminum alloy, cold-rolled steel plate, stainless steel, etc., for user selection. Standard busbars are used for low-voltage outgoing lines, available for side or top outgoing lines, and can also be designed for users’ specific outgoing line requirements.

As a custom manufacturer of transformers in China, conduct an in-depth study of the 500 KVA Dry Type Amorphous Alloy Transformer Product Structure and learn more about dry type transformer structure information. Contact us

Voltage Level of 500 KVA Dry Type Amorphous Alloy Transformer

| Rated capacity(KVA) | High voltage(KV) | High voltage fraction range(%) | Low voltage (KV) | Connection label | No load loss(W) | Load loss(W) | No-load current(%) | Impedance voltage(%) |

| 30 | 6 6.3 6.6 10 10.5 11 34.5 |

±5 +5×2.5 |

0.4 | Dyn11 | 70 | 710 | 1.6 | 4 |

| 50 | 90 | 1000 | 1.4 | |||||

| 80 | 120 | 1380 | 1.3 | |||||

| 100 | 130 | 1570 | 1.2 | |||||

| 125 | 150 | 1850 | 1.1 | |||||

| 160 | 170 | 2130 | 1.1 | |||||

| 200 | 200 | 2530 | 1 | |||||

| 250 | 230 | 2760 | 1 | |||||

| 315 | 280 | 3470 | 0.9 | |||||

| 400 | 310 | 3990 | 0.8 | |||||

| 500 | 360 | 4880 | 0.8 | |||||

| 630 | 420 | 5880 | 0.7 | |||||

| 630 | 410 | 5960 | 0.7 | |||||

| 800 | 480 | 6960 | 0.7 | 6 | ||||

| 1000 | 550 | 8130 | 0.6 | |||||

| 1250 | 650 | 9690 | 0.6 | |||||

| 1600 | 760 | 11730 | 0.6 | |||||

| 2000 | 1000 | 14450 | 0.5 | |||||

| 2500 | 1200 | 17170 | 0.5 | |||||

| 1600 | 760 | 12960 | 0.6 | 8 | ||||

| 2000 | 1000 | 15960 | 0.5 | |||||

| 2500 | 1200 | 18890 | 0.5 |

You may also find these interesting: