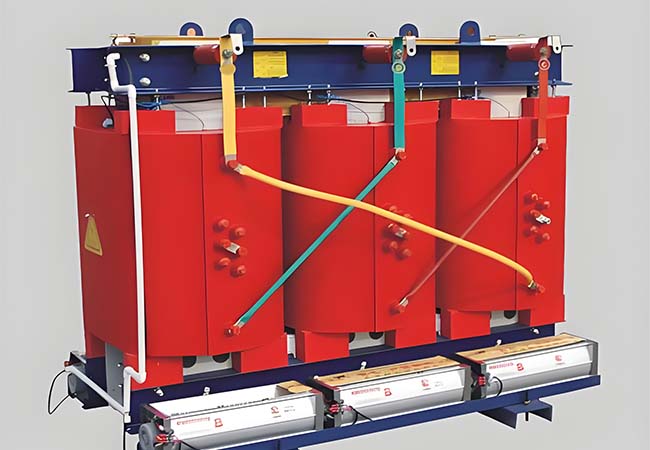

SCRBH15 Amorphous Alloy Dry-Type Transformer

04-10 2025 | By:

SCRBH15 Amorphous Alloy Dry-Type Transformer

Amorphous alloy dry-type transformers use advanced amorphous alloy materials, effectively reducing no-load losses by up to 60%-80%. China Electric Power’s amorphous alloy transformers have become the ideal choice for major data centers with their green and energy-saving environmental performance and excellent electrical performance, helping computing centers to usher in a new era of efficient, green and energy-saving electricity!

Amorphous Alloy Dry-Type Transformer Advanced technology

Unique semi-encapsulated three-phase three-column patented technology

Small size, light weight, resistant to high-order harmonics

Independent amorphous alloy core production line and production process

High efficiency and energy saving

Adopt amorphous alloy strip, high mechanical strength

No-load loss is reduced by 60%-80%, no-load current is reduced by 70%-85%

Nomex® insulation paper

Continuously placed at 220℃ can maintain effective performance for more than 10 years

200℃ UL material temperature, 3500v withstand voltage test

Amorphous Alloy Dry-Type Transformer Durable

Strong short-circuit resistance, long service life

Dustproof, moisture-proof, salt spray-proof

Excellent “three-proof” ability, no cracking

Amorphous Alloy Dry-Type Transformer 3D Design

Based on more than 30 years of experience in design, manufacturing and testing in the transformer industry, ZTELEC has developed a set of advanced “3D + parametric” design software that can realize automated design and cost optimization, simulation and emulation, fully considering national and industry standards and requirements to ensure the advanced design of products.

Low-voltage foil wound coil

It is made of high-quality copper foil and H-class insulation material wound on a molded insulation cylinder. The layer insulation is made of Nomex® paper, and VPI vacuum pressure impregnation is formed into a solid whole. The upper and lower ends are sealed with resin. The lead copper bar and copper foil are welded by argon arc with special equipment. The coil has high mechanical strength, strong short-circuit resistance, dustproof, moisture-proof and salt spray-proof capabilities.

High-voltage winding coil

The multi-layer segmented cylindrical coil and longitudinal multi-airway structure are used. They have strong heat and shock resistance and surge resistance. The conductor is Nomex® paper-wrapped flat copper wire, the insulation is Nomex® paper, and the end insulation is H-grade material. The high and low voltage coils are wound together, and the coils are cured by VPI vacuum pressure impregnation and high-temperature baking. The coils are a solid whole. The upper and lower ends are sealed with resin, which has good heat dissipation performance and will never crack.

Amorphous Alloy Dry-Type Transformer Core

The core structure is simple, and the iron loss is 70%-80% lower than that of conventional products. The unique process makes it have high mechanical strength, and its characteristics and structure will not be affected by transportation and vibration.

Testing and inspection technology

All products strictly control the production process and quality links. Before leaving the factory, ZTELEC conducts strict testing and inspection according to national standards and customer customization requirements, including partial discharge inspection, lightning impulse inspection, noise inspection and other mandatory inspection items. Advanced testing equipment and a complete inspection and testing system ensure the high quality of the products.

Performance Parameters

| Rated capacity (kVA) | Voltagegroup | Impedance voltage(%) | SC(B)10 | Sound leve (dB) | Dimension(mm) | Weight(kg) | ||||||

| HV(kV) | Tap range | LV(kV) | No-loadloss (W) | Loadloss120℃ (W) | No-load curren (%) | L | W | H | ||||

| 30 | 10 11 10.5 6.6 6.3 6 | ±2×2.5% ±5% | 0.4 | 4 | 190 | 710 | 2.0 | 44 | 620 | 400 | 600 | 220 |

| 50 | 270 | 1000 | 2.0 | 44 | 650 | 400 | 740 | 320 | ||||

| 80 | 370 | 1380 | 1.5 | 45 | 750 | 500 | 770 | 460 | ||||

| 100 | 400 | 1570 | 1.5 | 45 | 800 | 500 | 830 | 580 | ||||

| 125 | 470 | 1850 | 1.3 | 46 | 950 | 880 | 1090 | 750 | ||||

| 160 | 540 | 2130 | 1.3 | 46 | 950 | 880 | 1090 | 780 | ||||

| 200 | 620 | 2530 | 1.1 | 47 | 1050 | 900 | 1200 | 850 | ||||

| 250 | 720 | 2760 | 1.1 | 48 | 1050 | 900 | 1200 | 1030 | ||||

| 315 | 880 | 3470 | 1.0 | 48 | 1080 | 900 | 1250 | 1060 | ||||

| 400 | 980 | 3990 | 1.0 | 49 | 1110 | 950 | 1270 | 1400 | ||||

| 500 | 1160 | 4880 | 1.0 | 49 | 1130 | 950 | 1380 | 1550 | ||||

| 630 | 1340 | 5880 | 0.85 | 49 | 1200 | 950 | 1450 | 1820 | ||||

| 630 | 6 | 1300 | 5960 | 0.85 | 50 | 1320 | 950 | 1375 | 1850 | |||

| 800 | 1520 | 6960 | 0.85 | 51 | 1310 | 1000 | 1315 | 2150 | ||||

| 1000 | 1770 | 8130 | 0.85 | 52 | 1400 | 1070 | 1520 | 2550 | ||||

| 1250 | 2090 | 9690 | 0.85 | 53 | 1440 | 1150 | 1570 | 3020 | ||||

| 1600 | 2450 | 11730 | 0.85 | 54 | 1650 | 1200 | 1795 | 4500 | ||||

| 2000 | 3050 | 14450 | 0.7 | 55 | 1800 | 1260 | 1870 | 5300 | ||||

| 2500 | 3600 | 17170 | 0.7 | 56 | 1950 | 1260 | 2035 | 6200 | ||||

| Rated capacity (kVA) | Voltagegroup | mpedance voltage(%) | SC(B)11 | Sound eve (dB) | Dimension(mm) | Weight(kg) | ||||||

| HV(kV) | Tap range | LV(kV) | No-loadloss (W) | Loadloss120℃ (W) | No-load current (%) | L | W | H | ||||

| 30 | 10 11 10.5 6.6 6.3 6 | ±2×2.5% ±5% | 0.4 | 4 | 170 | 710 | 2.0 | 44 | 620 | 400 | 600 | 220 |

| 50 | 250 | 1000 | 2.0 | 44 | 650 | 400 | 740 | 320 | ||||

| 80 | 330 | 1380 | 1.5 | 45 | 750 | 500 | 770 | 460 | ||||

| 100 | 360 | 1570 | 1.5 | 45 | 800 | 500 | 830 | 580 | ||||

| 125 | 420 | 1850 | 1.3 | 46 | 950 | 880 | 1090 | 750 | ||||

| 160 | 490 | 2130 | 1.3 | 46 | 950 | 880 | 1090 | 780 | ||||

| 200 | 560 | 2530 | 1.1 | 47 | 1050 | 900 | 1200 | 850 | ||||

| 250 | 650 | 2760 | 1.1 | 48 | 1050 | 900 | 1200 | 1030 | ||||

| 315 | 790 | 3470 | 1.0 | 48 | 1080 | 900 | 1250 | 1060 | ||||

| 400 | 880 | 3990 | 1.0 | 49 | 1110 | 950 | 1270 | 1400 | ||||

| 500 | 1040 | 4880 | 1.0 | 49 | 1130 | 950 | 1380 | 1550 | ||||

| 630 | 1210 | 5880 | 0.85 | 49 | 1200 | 950 | 1450 | 1820 | ||||

| 630 | 6 | 1170 | 5960 | 0.85 | 50 | 1320 | 950 | 1375 | 1850 | |||

| 800 | 1370 | 6960 | 0.85 | 51 | 1310 | 1000 | 1315 | 2150 | ||||

| 1000 | 1590 | 8130 | 0.85 | 52 | 1400 | 1070 | 1520 | 2550 | ||||

| 1250 | 1880 | 9690 | 0.85 | 53 | 1440 | 1150 | 1570 | 3020 | ||||

| 1600 | 2210 | 11730 | 0.85 | 54 | 1650 | 1200 | 1795 | 4500 | ||||

| 2000 | 2750 | 14450 | 0.7 | 55 | 1800 | 1260 | 1870 | 5300 | ||||

| 2500 | 3240 | 17170 | 0.7 | 56 | 1950 | 1260 | 2035 | 6200 | ||||

You may also find these interesting: