Types of Dry Type Transformer

10-22 2024 | By:

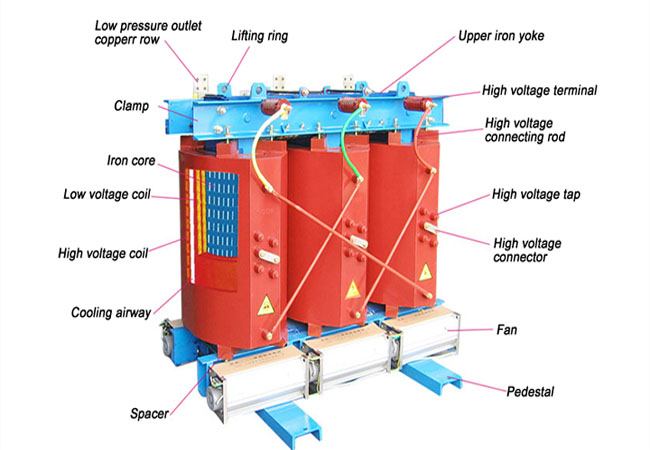

A dry-type transformer refers to a transformer whose core and windings are not immersed in insulating oil. There are two types of dry-type transformer cooling: natural air cooling (AN) and forced air cooling (PF). There are two types of dry-type transformer structures: fixed insulation encapsulation (SCB type) and unencapsulated winding structure. From the relative position of the high and low voltage windings, there are two types: concentric and overlapping. The concentric structure is simple and easy to manufacture. Most dry-type transformers use this structure. The overlapping type is mainly used in the manufacture of special transformers.

Dry type transformer manufacturer

Dry-type Transformer Specifications

Take SCB-11—1250KVA/10KV/0.4KV dry-type transformer as an example to explain the meaning of dry-type transformer models: In the above model specifications, S represents a three-phase power transformer, C represents that the transformer winding is a resin-cast solid, G represents that the outer insulation medium of the winding is air, B represents a parked winding, R represents a wound winding, 11 is the series number, 1250KVA is the rated capacity of the transformer, 10KV is the rated voltage of the primary side of the transformer, and 0.4KV is the rated voltage of the secondary side of the transformer.

Technical parameters of dry-type transformer

①Frequency 50Hz/60Hz

②No-load current, required to be less than 4%

③Low-voltage withstand voltage: 2KV/min without breakdown

④Insulation resistance low-voltage side not less than 2MΩ

⑤Winding connection method: /Y/yn0, and D/yn0

⑥Coil allowable temperature rise 100K

⑦Cooling method: natural air cooling or temperature-controlled air cooling

⑧Noise coefficient less than 30dB

SCB10 dry type transformer

Types of Dry-Type Transformers

1. Impregnated air-insulated dry-type transformers: Currently, they are rarely used. Winding conductor insulation and insulation structure materials are selected from insulation materials of different heat-resistant grades according to needs to make B-class, F-class and H-class insulation dry-type transformers.

2. Epoxy resin cast dry-type transformers: The insulation materials used are polyester resin and epoxy resin. Currently, epoxy resin is mostly used in cast insulation dry-type power transformers.

3. Wrap insulation dry-type transformers: Wrap insulation dry-type transformers are also a type of resin insulation. Currently, there are few manufacturers.

4. Composite insulation dry-type transformers:

(1) High-voltage windings use cast insulation, and low-voltage windings use impregnated insulation;

(2) High voltage uses cast insulation, and low voltage uses foil windings wound with copper foil or aluminum foil.

Dry type transformer type

Performance Parameters

| Rated capacity (kVA) | Voltagegroup | Vector group | Loss (W) | No-load current(%) | Impedance voltage (%) | Weight (Kg) | Boundary dimension (L×W×H,mm) | Gauge | ||

| HV (kV) | LV (kV) | No-loadloss(W) | Loadloss75℃ | Longitudinal/transverse (mm) | ||||||

| 100 | 11 10.5 10 6.3 6 | 0.4 | Dyn11 | 130 | 1570 | 1.2 | 4 | 890 | 950×600×960 | 550×550 |

| 160 | 170 | 2130 | 1.1 | 1170 | 1220×600×1060 | 550×550 | ||||

| 200 | 200 | 2530 | 1.0 | 1400 | 1270×710×1160 | 660×660 | ||||

| 250 | 230 | 2760 | 1.0 | 1560 | 1350×760×1240 | 660×660 | ||||

| 315 | 280 | 3470 | 0.9 | 1770 | 1370×870×1360 | 820×820 | ||||

| 400 | 310 | 3990 | 0.8 | 2180 | 1460×870×1360 | 820×820 | ||||

| 500 | 360 | 4880 | 0.8 | 2440 | 1490×870×1430 | 820×820 | ||||

| 630 | 420 | 5880 | 0.7 | 2850 | 1760×1120×1490 | 1070×1070 | ||||

| 630 | 410 | 5960 | 0.7 | 6 | 3015 | 1710×970×1450 | 1070×1070 | |||

| 800 | 480 | 6960 | 0.7 | 3430 | 1850×1120×1600 | 1070×1070 | ||||

| 1000 | 550 | 8130 | 0.6 | 4050 | 1900×1120×1170 | 1070×1070 | ||||

| 1250 | 650 | 9690 | 0.6 | 4690 | 2030×1120×1880 | 1070×1070 | ||||

| 1600 | 760 | 11730 | 0.6 | 5610 | 2120×1120×1970 | 1070×1070 | ||||

| 2000 | 1000 | 14450 | 0.5 | 5820 | 2120×1120×1990 | 1070×1070 | ||||

| 2500 | 1200 | 17170 | 0.5 | 6730 | 2190×1120×2110 | 1070×1070 | ||||

You may also find these interesting: