Copyright © 2022 ZTelec Group. All rights reserved.

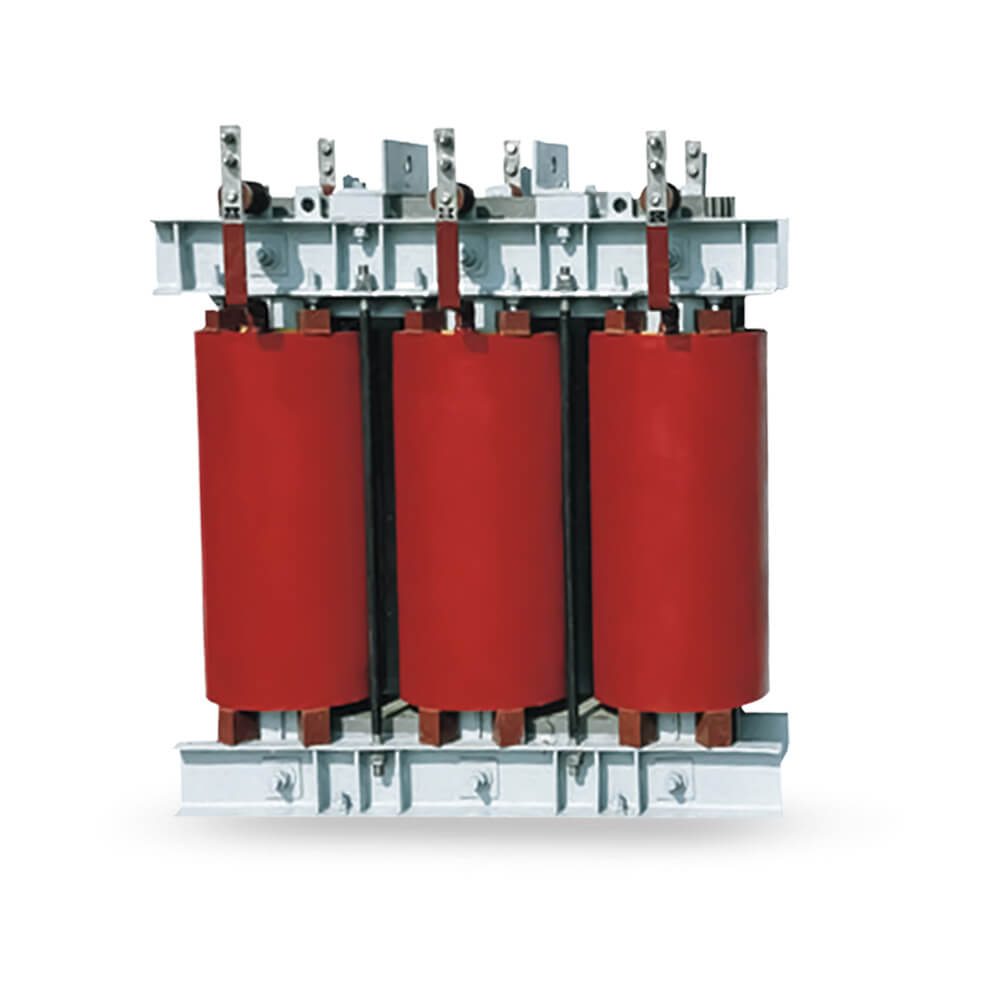

1600 kVA Dry Type Cast Resin Transformer 20kv 21kv 22kv – Transformer and Power Transformer

| Rated voltage | 20kV-24kV |

|---|---|

| Rated capacity | 30kVA-5000kVA |

| Application scenarios | The product is widely used in power transmission and transformation systems,such as hotels,restaurants,airports,high-rise buildings, commercial centers,residential quarters and other important places,as well as subways,smelting power plants and other harsh environments. |