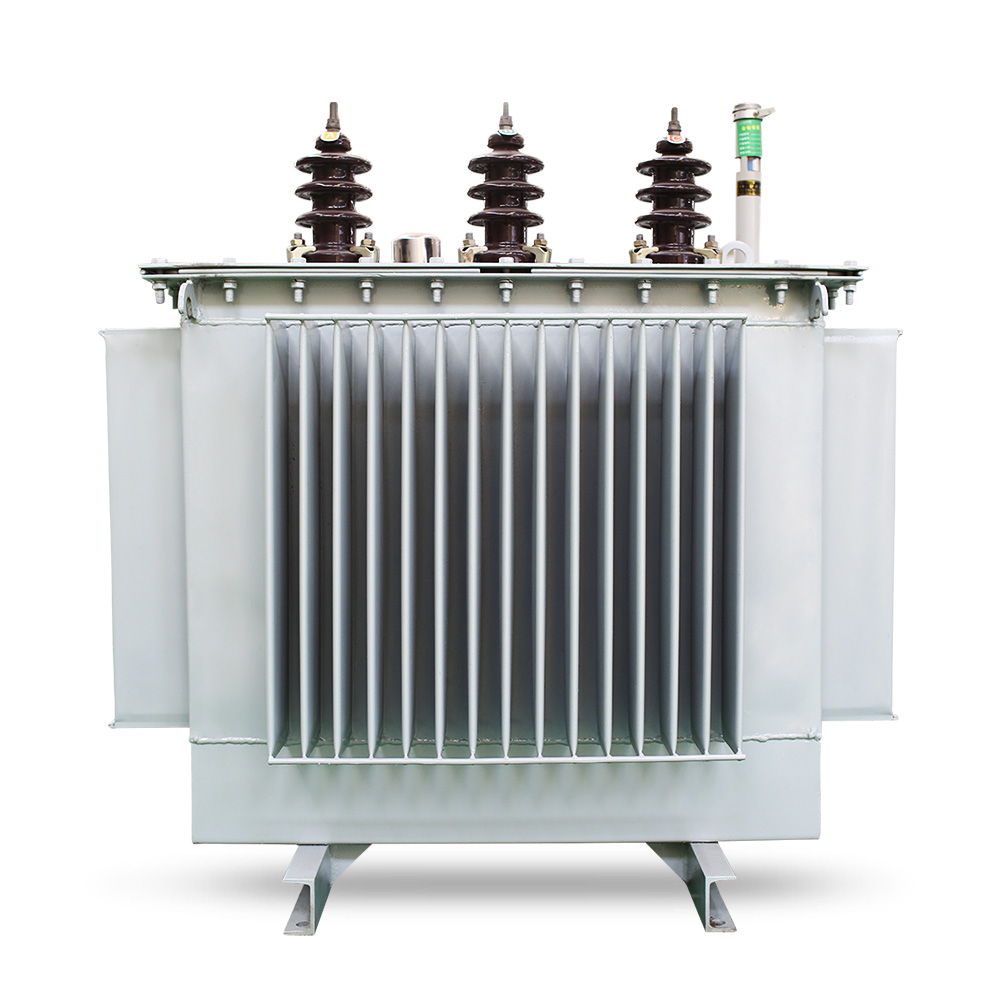

Equipment Display

The oil-immersed transformer is similar to the transformer in structure. It is one of the transformer types classified by the form of insulation of the core. Therefore, it has the recognizable feature of oil-immersed coils, which can reduce the thermal image of the equipment in it.

The basic elements of oil-immersed type consist of core, winding and bushing. The core provides a path for magnetic flow. The winding creates a magnetic field. It consists of a conductor coil, which is wound on the core and insulated with a cardboard barrier and shield. The thickness of the insulation layer of the winding increases with the increase of voltage. The bushing connects the transformer winding to the substation.

Oil-immersed transformers are used in power distribution or substations. Their core and coils are immersed in oil, which cools and insulates. The oil circulates through the pipes in the coils and around the coils and core assembly by moving by convection. The oil is cooled by the outside of the tank at small ratings and by air-cooled radiators at large ratings.

Purpose of using oil-immersed transformers

Oil transformers can be mounted on the ground, pedestals or poles for outdoor use. They provide efficient performance in a variety of applications, including power transmission and distribution networks, renewable energy generation, and small industries.

Oil transformers have a huge capacity, so they will save a lot of electricity, minimize power loss, save energy, and reduce user costs. Not only that, the oil in the machine can also cool the internal wire core, thereby improving the durability and electrical performance of the transformer equipment.

Features

+The three-phase ollimmersed transformer produced by our company uses a newinsulating structure to improve the ability to withstand short-circuits. The iron core is made of high-quality cold-rolled silicon steel sheet, and the winding is made of multilayer cylinder or foil structure. All fasteners adopt special anti-loose treatment;

+The product has the characteristics of high efficiency and low loss. It can greatly save power consumption and operating costs, bringing significant social benefits. It is the national high-tech product.

Implementation Standards

GBT6451-2015:Oil immersed power transformer technical parameters and requirements

GB 1094. 1-2013:Power transformers Part 1:General rules

GB 1094. 2-2013:Power transformers Part 2:Temperature rise of liquid immersed transformers

GB 1094. 5-2008:Power transformers Part 5:Capability to withstand short circuit

GBT 1094. 7-2008:Power transformers Part 7:Load guidelines for oil immersed power transformers.

Regular Service Conditions

a The Elevation (m. a. s. l. )is below 1000m;

b Ambient temperature;

C Highest ambient temperature +40℃;

d Highest daily average air temperature +20℃;

e Lowest outdoor ambient temperature -25℃;