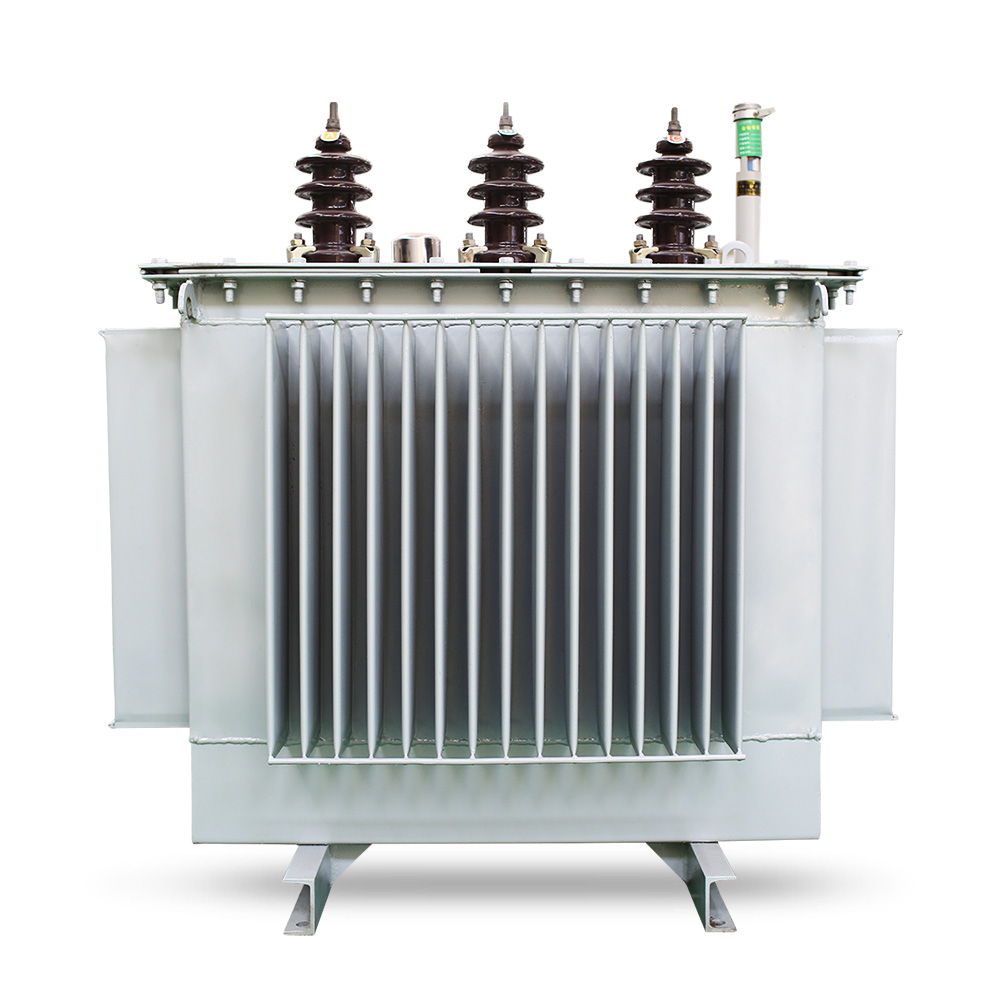

Equipment Display

ZTELEC Electric Technology (Zhengzhou) Co., Ltd Oil-Immersed Transformer

The oil-immersed transformer is similar to the transformer in structure. It is one of the transformer types classified by the form of insulation of the core. Therefore, it has the recognizable feature of oil-immersed coils, which can reduce the thermal image of the equipment in it.

The basic elements of oil-immersed type consist of core, winding and bushing. The core provides a path for magnetic flow. The winding creates a magnetic field. It consists of a conductor coil, which is wound on the core and insulated with a cardboard barrier and shield. The thickness of the insulation layer of the winding increases with the increase of voltage. The bushing connects the transformer winding to the substation.

Oil-immersed transformers are used in power distribution or substations. Their core and coils are immersed in oil, which cools and insulates. The oil circulates through the pipes in the coils and around the coils and core assembly by moving by convection. The oil is cooled by the outside of the tank at small ratings and by air-cooled radiators at large ratings.

Purpose of using oil-immersed transformers

Oil transformers can be mounted on the ground, pedestals or poles for outdoor use. They provide efficient performance in a variety of applications, including power transmission and distribution networks, renewable energy generation, and small industries.

Oil transformers have a huge capacity, so they will save a lot of electricity, minimize power loss, save energy, and reduce user costs. Not only that, the oil in the machine can also cool the internal wire core, thereby improving the durability and electrical performance of the transformer equipment.

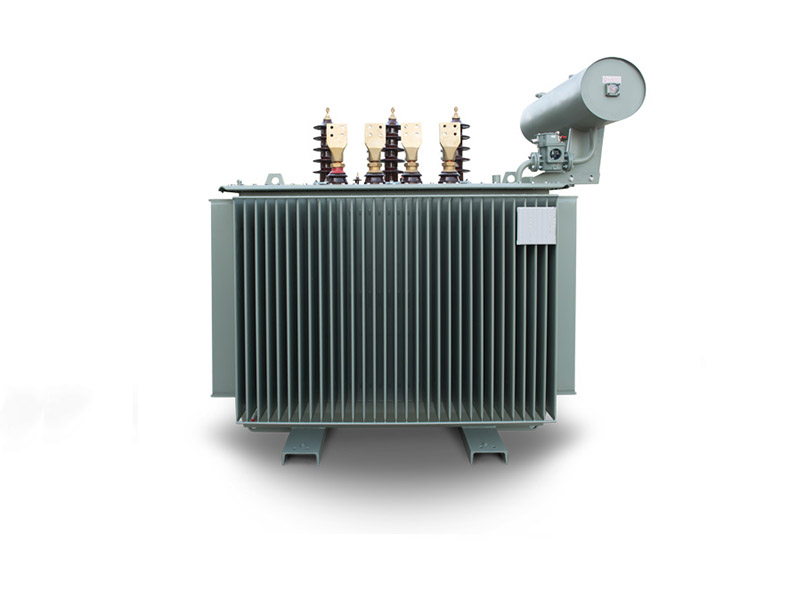

Features

The fully sealed transformer adopts a fully oil-filled sealed type. The shell of the corrugated oil tank adapts to the expansion of the oil with its own elasticity and it is a sealed oil tank, which has been widely used in various power distribution equipment

+The iron core is made of high-quality cold-rolled oriented silicon steel sheet, which is manufactured by the automatic cross-cutting process and the the step lap process, which improves the distribution of magnetic flux density inside the iron core, reduces the vibration energy of the iron core, and effectively reduces the noise and loss;

+The coil is winded with high-strength enameled wire (or paper-covered wire), cylindrical (or cake)structure with uniform ampere-turn distribution, reasonable insulation structure, and strong short-circuit resistance;

+The transformer body is fastened with an anti-loosening structure, the fastening part is equipped with locknut, and the non hanging core structure is adopted to ensure that it will not come loose after long-distance transportation;

+The corrugated sheet of the corrugated oil tank replaces the oil conservator. The corrugated sheet can expand and shrink with the change of the transformer oil volume, isolate the transformer from the atmosphere, prevent and slow down the deterioration of the oil and insulation being affected with damp, enhance the reliability of operation, and keep the transformer operate normally without maintenance;

+Equipped with “remote monitoring”signal thermometer and pressure release valve, which enhances the reliability of transformer operation.