Description

What is an Amorphous metal transformer?

Amorphous metal transformer are designed to reduce transformer losses and no-load losses during operation. The key part is the iron core. Amorphous metal transformer use amorphous metal instead of silicon steel sheets as the material for making them. This makes them a new type of energy-saving transformer

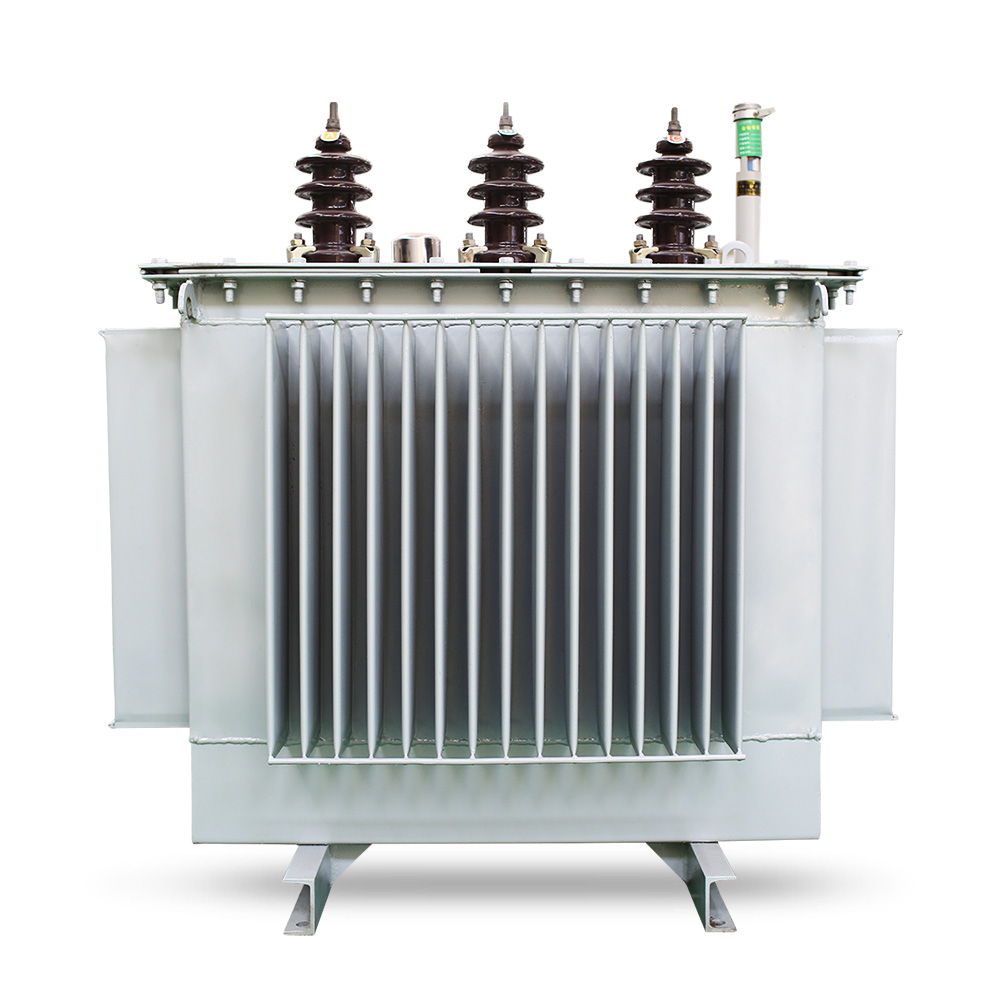

The amorphous alloy version of the oil transformer is basically more regular than ordinary transformers in appearance, and many transformers are “flat”.

What is an Amorphous alloy?

Amorphous alloy is a material with an amorphous alloy structure made of iron, indium, silicon, boron, carbon, etc., prepared in a certain proportion and made by rapid cooling process. Today, in the manufacture of transformers, this material is used in products such as dry and oil-immersed transformers.

What are the advantages of amorphous alloy oil-immersed transformers?

The main reason is that it can effectively reduce the no-load loss of the transformer, thereby achieving the purpose of energy saving and loss reduction. Tests show that the iron loss of amorphous alloys is reduced by more than 70% to 80% compared with silicon steel. It reduces losses, decreases the demand for power generation, and is more in line with the concept of energy conservation and environmental protection.

Features

+Amorphous alloy is a new type energy-saving material. Its metal atoms are disorderly amorphous, and its crystal structure is completely diferent from that of silicon steel, which is more conducive to magnetization and demagnetization. The iron core sheet is extremely thin, only 0. 025mm, even thinner than one tenth of the thickness of ordinary silicon steel sheet. This new material is used for transformer cores, with the features of high saturation magnetic induction, low loss, low excitation current, and good temperature stability. Amorphous alloy transformer has the advantages of low no-load loss, strong anti-short-circuit capability, advanced structure, energy saving, and obvious environmental protection, and is an ideal option for energy saving currently.

Why Choose Us

Manufacturer with two decades of experience in supplying power transmission and distribution equipment.

● Served 57 countries with 1000+ cases

● 38 R & D technicians

● 90000 m2 workshop

● Cooperate with 16 world famous brand

● OEM of Schneider for 10 years