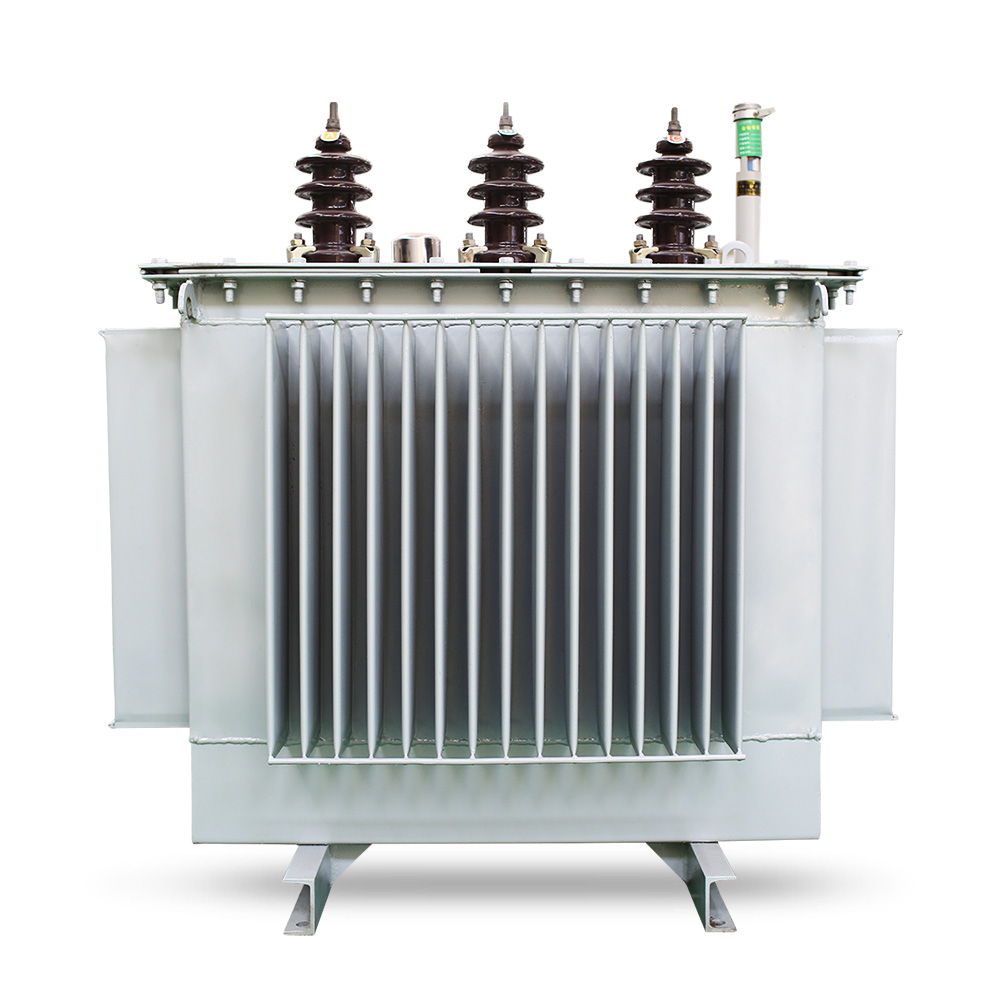

Equipment Display

Description

Three-dimensional wound core transformers, three-dimensional combined wound core transformers, three-dimensional combined three-phase wound core transformers, triangular three-dimensional wound core transformers, three-dimensional triangular wound core transformers, etc. all refer to three-dimensional wound core transformers, and the letters RL appear in their models. Such as S13-MRL-6300/10, SCB11-RL-1000/10, where R represents the rolled core and L represents the three-dimensional structure.

The three-dimensional wound core transformer is an energy-saving power transformer. It creatively reforms the laminated magnetic circuit structure and three-phase layout of the traditional power transformer, making the product performance more optimized, such as the three-phase magnetic circuit is completely symmetrical and the power-saving effect Significantly, the noise is greatly reduced, the heat dissipation and overload capacity are stronger, the structure is compact and the volume is small.

The three-dimensional wound core transformer is an energy-saving power transformer that creatively reforms the laminated magnetic circuit structure and three-phase layout of traditional power transformers, making the product performance more optimized.

The key component of the three-dimensional wound core transformer is the three-dimensional wound core, which is made up of three single-frame cores of the same size. The cross-sections of the stem and iron yoke of each single-frame iron core are equal and close to a semicircle. After being combined, the three stems of the core are arranged in an equilateral triangle shape. The cross-section of the core pillars is close to a circle. The length of the magnetic circuit of the three cores is The iron yoke length is the shortest, so the iron core is light and the no-load loss is small.

Features

+The series of oil immersed transformers breaks through the traditional planar structure and adopts a three-phase symmetrical three-dimensional structure. The magnetic circuit of the three phase iron core is completely symmetrical, the magnetic resistance is greatly reduced, and the excitation current and no-load loss are significantly reduced. It is an energy-efficient transformer that uses traditional materials but has lower noise and compact structure. Its outstanding performance in energy conservation and environmental protection is completely in compliance with China’s energy conservation policy.

1. Magnetic circuit optimization

(1) There are no seams between the layers of the three-dimensional wound core, and the magnetic circuit is evenly distributed throughout. There is no obvious high-resistance area, and there is no distortion of the magnetic flux density at the seams.

(2) The direction of the magnetic flux is completely consistent with the crystal orientation of the silicon steel sheet.

(3) The three-phase magnetic circuit lengths are completely equal, and the sum of the three-phase magnetic circuit lengths is the shortest.

(4) The three-phase magnetic circuit is completely symmetrical, and the three-phase no-load current is completely balanced.

2. Low loss and significant power saving effect

(1) The magnetization direction of the three-dimensional rolled core is completely consistent with the rolling direction of the silicon steel sheet, and there is no overlap between the core layers. The magnetic flux is evenly distributed throughout the magnetic circuit, with no obvious high-resistance areas and no seams. The distortion phenomenon of magnetic flux density. Under the premise of the same material, compared with the laminated core, the iron loss process coefficient of the wound core decreases from 1.3-1.5 to about 1.05. This alone can reduce the core loss by 10-20%.

(2) Due to the special three-dimensional structure, the material used in the iron yoke part of the core is reduced by 25% compared with the traditional laminated core, and the reduced angular weight accounts for about 6% of the total weight of the core.

(3) The shearing treatment of the silicon steel sheet will deteriorate its magnetic permeability. The three-dimensional rolled core is subjected to high-temperature (800°C) vacuum nitrogen-filled annealing treatment, which not only eliminates the mechanical stress of the core, but also refines the magnetic properties of the silicon steel sheet. domain, which improves the secondary recrystallization ability of the silicon steel sheet, making the performance of the silicon steel sheet much better than its factory performance.

(4) After testing, it has been determined that the no-load loss of the three-dimensional transformer is 25-35% lower than the national standard, and the no-load current can be reduced by up to 92%.

3. Low noise

The root causes of noise caused by the vibration of the transformer body are:

1) The magnetostriction of the silicon steel sheet causes the iron core to vibrate and produce noise.

2) There is electromagnetic attraction caused by magnetic flux leakage between the joints of silicon steel sheets and the laminations, causing the core to vibrate and generate noise.

3) The working magnetic density of the transformer is too high, approaching or reaching the saturation point, and the magnetic leakage is too large, causing noise.

Since the three-dimensional rolled core is made by rolling silicon steel sheet strips continuously and tightly on a dedicated core winding machine, there are no seams and no noise caused by discontinuous magnetic circuits like the laminated rush. . At the same time, the three-phase magnetic circuit and magnetic flux are completely symmetrical, and the working magnetic density is reasonably designed, so the product noise is greatly reduced.

The type test sound level of the SGB10-RL-2000/10 product is only 47dB, which is 19dB lower than the 66dB specified in the national standard. It is almost environmentally friendly and silent, and is most suitable for indoor and residential use.

4. Strong overload capability

(1) The calorific value of the product itself is very low: the no-load loss and no-load current of the wound core transformer are very small, and the calorific value of the product itself is very low;

(2) As shown in Figure 1, the three-phase coils are arranged in a “pin” shape, forming a central natural gas channel running up and down between the coils – the “exhaust chimney”. Due to the 30-40°C temperature difference between the upper and lower iron yokes, a strong Due to the air convection, cold air is replenished from the bottom to the central channel, and the heat is radiated from the inner slope of the upper iron yoke, and the heat generated by the transformer is quickly taken away in natural circulation.

5. Compact structure and small footprint

The special three-dimensional iron core makes the product compact in structure and rational in layout. The plane area of the unit is reduced by 10-15% compared with traditional products, and the height of the unit is reduced by 10-20%. If installed in a box-type substation, the volume of the box transformer can be reduced by nearly 1 /4.