Dry Type Iron Core High Voltage Series Harmonic Filter Reactor

Dry Type Iron Core Series Reactor Product Application

Our company can produce CKSC series dry-type iron core series reactors with voltage levels of 35kV and below and capacities of 2000kVar and below.

The series reactor is connected in series with the high-voltage capacitor bank and connected to the 6-35kV power system to limit the inrush current of the parallel capacitor bank and suppress the harmonics of the power grid.

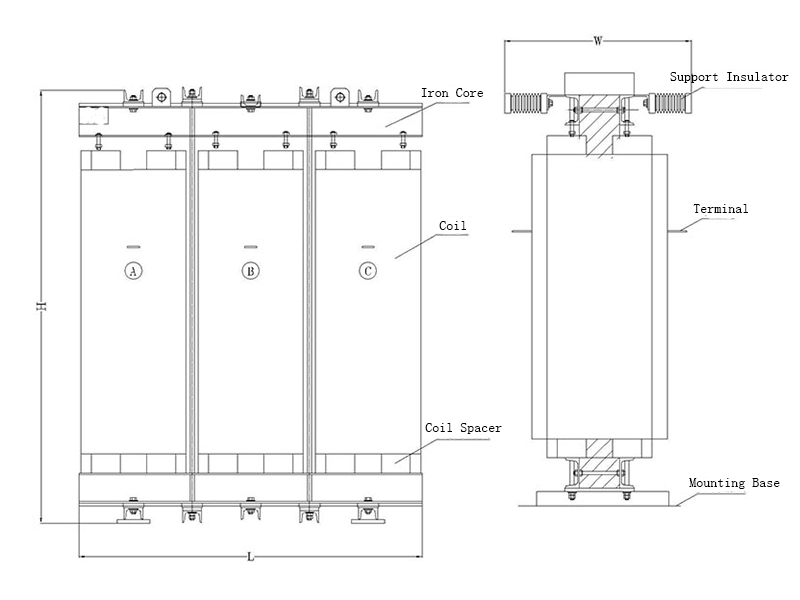

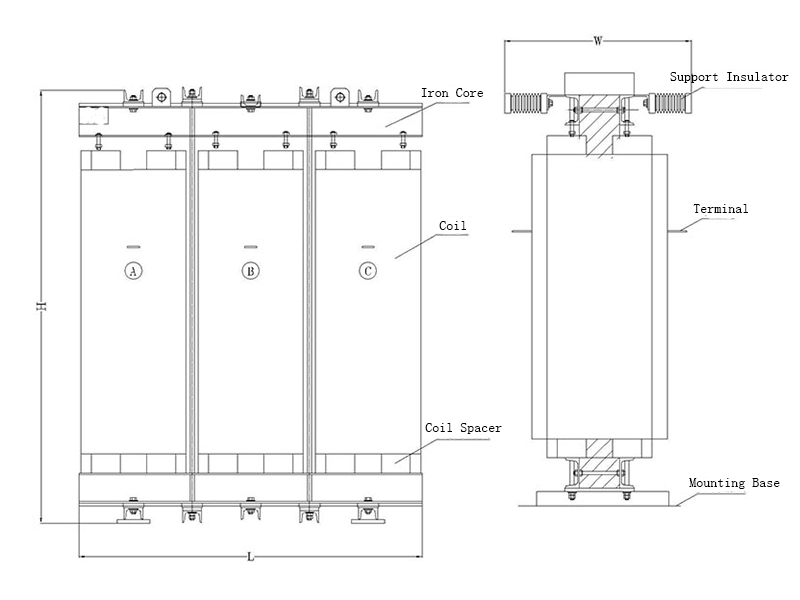

Dry Type Iron Core Series Reactor Structure

The iron core series reactor has two main structures: the iron core and the coil.

Dry-type iron core series reactor core is a three-column core structure. The core column is composed of stepped or radial discus, and the upper and lower iron yokes are rectangular or circular. The core is made of high-quality cold-rolled silicon steel sheets. In order to reduce the noise of the core, the core disc is cast and encapsulated as a whole with high-strength resin. The air gap between the core discs is composed of several small air gap segments, which can reduce the core loss and reduce noise. The core disc is pressed into a whole by a low-magnetic screw and an iron yoke. In order to reduce the vibration of the core during operation, shock-absorbing materials are used between the core and the reactor base for buffering.

The coil is wound with copper or aluminum wire wrapped with high-quality insulating materials. In order to prevent the generation of circulating current between multiple wires during the winding process, the wire is completely transposed. After the coil is wound, two-component epoxy resin is used to cast the coil under vacuum to ensure that there is no air gap between the turns and layers of the winding, thereby reducing partial discharge of the product.

Schematic diagram of dry-type iron core series reactor structure

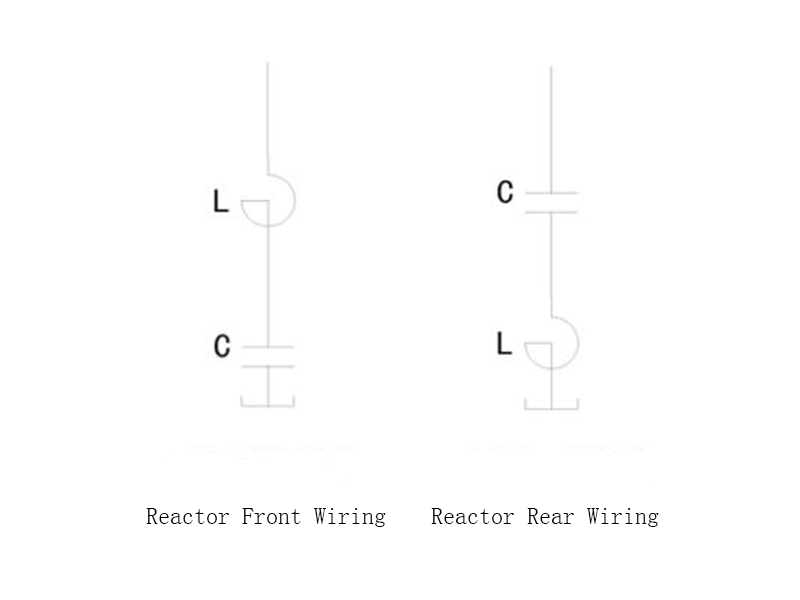

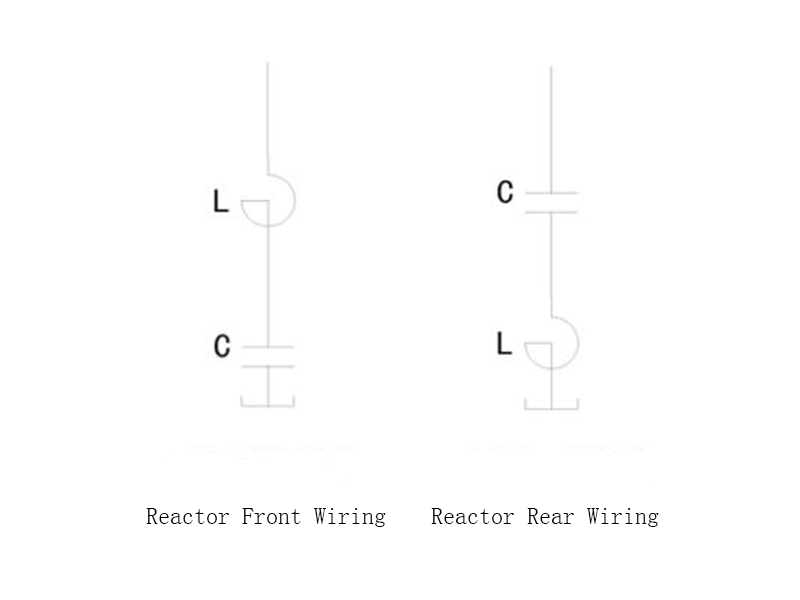

Dry Type Iron Core Series Reactor Wiring Method

Dry Type Iron Core Series Reactor Product Features

1) The CKSC dry-type iron core reactor adopts a dry-type iron core structure, three-phase coexistence, the iron core is made of high-quality silicon steel sheets, the iron core column is composed of multiple air gaps evenly distributed, and the air gap uses epoxy glass cloth board as a filler to ensure that the gap does not change during long-term operation.

2) The overall structure of the dry-type iron core reactor is simple, small in size, light in weight, reasonable in layout, and easy to install. It is an ideal supporting equipment for indoor capacitor compensation frames and cabinet devices, and has no electromagnetic pollution, no oil pollution, good flame retardancy, less leakage magnetic flux, and low electromagnetic interference to the environment.

3) The coil is epoxy casting type, and epoxy glass mesh cloth is laid inside and outside the coil for reinforcement. The epoxy casting system is cast in a vacuum state, with excellent heat dissipation performance, good insulation performance, high mechanical strength, good dynamic thermal stability, and no cracking.

4) The epoxy casting coil does not absorb water, has low partial discharge, and can operate safely under harsh environmental conditions.

5) The gap between the core column and the insulating tube is fixed with epoxy resin glue, and the upper wire iron yoke and the coil are tightened with a pull screw to make the core and the coil integrated, which strengthens the insulation strength between the core and the coil and greatly reduces the operating noise of the reactor.

6) Special insulation components are installed between the coil and the core, and between the core and the ground to ensure the electrical insulation distance.

7) The reactor core and winding are not immersed in any liquid. The cooling method is air self-cooling, without oil leakage, easy to manufacture and maintain, and easy to operate.

8) Special computer software is used for auxiliary optimization design, the inductance value is accurate, and the temperature rise has a reasonable margin.

Regular Service Conditions

1. The altitude does not exceed 1000 meters.

2. Operating environment temperature -25 ° C – +45 ° C, relative humidity does not exceed 90%

3. There are no harmful gases around, no flammable or explosive materials.

4. The surrounding environment should have good ventilation conditions.The altitude does not exceed 1000 meters.

Ordering Instructions

System Rated Voltage

Capacitor Bank Rated Voltage

Reactor Rated Capacity

Reactor Rated Current

Rated Reactance Ratio

Performance Parameters

Rated Capacity

(KVAR) |

Type |

Rated Voltage

Line(KV) |

Terminal

Voltage(V) |

Terminal

Current(A) |

Reactance

Rate(%) |

Loss(W) |

Capacitor

Capacity(KVAR) |

Weight(Kg) |

| 12 |

CKSC-12/10-6 |

11 |

381 |

10.5 |

6 |

720 |

200 |

180 |

| 24 |

CKSC-24/10-6 |

11 |

381 |

21 |

6 |

750 |

400 |

290 |

| 36 |

CKSC-36/6-6 |

6.6 |

228 |

52.6 |

6 |

1050 |

600 |

350 |

| 36 |

CKSC-36/10-6 |

11 |

381 |

31.5 |

6 |

1050 |

600 |

350 |

| 60 |

CKSC-60/6-6 |

6.6 |

228 |

87.7 |

6 |

1650 |

1000 |

450 |

| 60 |

CKSC-60/10-6 |

11 |

381 |

52.5 |

6 |

1650 |

1000 |

450 |

| 90 |

CKSC-90/6-6 |

6.6 |

228 |

131 |

6 |

1800 |

1500 |

650 |

| 90 |

CKSC-90/10-6 |

11 |

381 |

78.7 |

6 |

1800 |

1500 |

650 |

| 108 |

CKSC-108/6-6 |

6.6 |

228 |

157.5 |

6 |

2350 |

1800 |

700 |

| 108 |

CKSC-108/10-6 |

11 |

381 |

94.5 |

6 |

2350 |

1800 |

700 |

| 120 |

CKSC-120/6-6 |

6.6 |

228 |

175 |

6 |

2750 |

2000 |

780 |

| 120 |

CKSC-120/10-6 |

11 |

381 |

105 |

6 |

2750 |

2000 |

780 |

| 150 |

CKSC-150/6-6 |

6.6 |

228 |

219 |

6 |

2860 |

2500 |

1050 |

| 150 |

CKSC-150/10-6 |

11 |

381 |

131.2 |

6 |

2860 |

2500 |

1050 |

| 180 |

CKSC180/6-6 |

6.6 |

228 |

263 |

6 |

2950 |

3000 |

1250 |

| 180 |

CKSC-180/10-6 |

11 |

381 |

157.5 |

6 |

2950 |

3000 |

1250 |

| 240 |

CKSC-240/6-6 |

6.6 |

228 |

351 |

6 |

3450 |

4000 |

1450 |

| 240 |

CKSC-240/10-6 |

11 |

381 |

210 |

6 |

3450 |

4000 |

1450 |

| 300 |

CKSC-300/10-6 |

11 |

381 |

262.5 |

6 |

4260 |

5000 |

1650 |

| 360 |

CKSC-360/10-6 |

11 |

381 |

315 |

6 |

4850 |

6000 |

2200 |

| 450 |

CKSC-450/10-6 |

11 |

381 |

394 |

6 |

5430 |

7000 |

2400 |

| 600 |

CKSC-600/10-6 |

11 |

381 |

525 |

6 |

5840 |

10000 |

3200 |

Ordering Guide

We accept OEM business. The above specifications are commonly used and are for reference only. They can be customized according to customer requirements.If it is a modification project, please inform the original equipment nameplate, drawings and reason for replacement. In this way, we can recommend you an alternative solution.