SVG Dry-type Iron Core Line Reactor

SVG (reactive power compensation) Dry-type Iron Core Line Reactor

The SVG line reactor is connected to the front end of the SVG device, and its functions are as follows:

It is used to connect the SVG device and the power grid to achieve energy buffering;

It reduces the ripple of the SVG switch and reduces common-mode interference;

It suppresses the current mutation when the inverter is connected to the power grid and achieves current smoothing;

When necessary, it can change the grid voltage to a voltage suitable for the inverter operation.

SVG (reactive power compensation) Dry-type Iron Core Line Reactor

Our company can produce CKSC series SVG (reactive power compensation) dry-type iron core line reactors with voltage levels of 35kV and below, currents of 25A~1000A, and inductances of more than 0.6mH

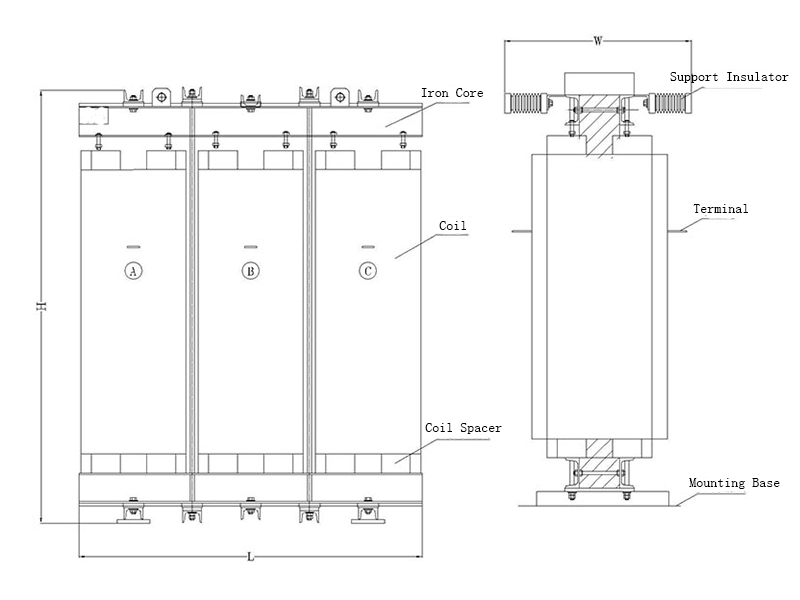

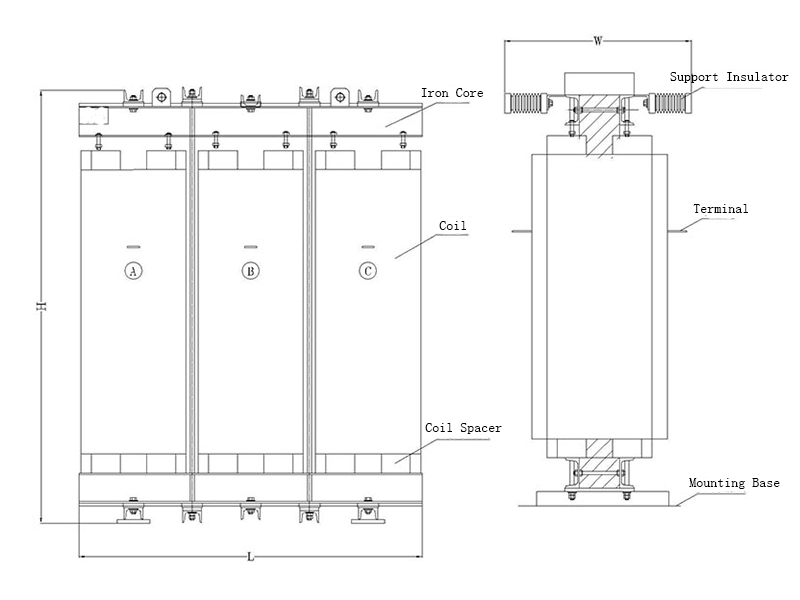

SVG Dry-type Iron Core Line Reactor Product Structure

The iron core series reactor has two main structures: the iron core and the coil.

SVG Dry-type Iron Core Line Reactor core is a three-column core structure. The core column is composed of stepped or radial discus, and the upper and lower iron yokes are rectangular or circular. The core is made of high-quality cold-rolled silicon steel sheets. In order to reduce the noise of the core, the core disc is cast and encapsulated as a whole with high-strength resin. The air gap between the core discs is composed of several small air gap segments, which can reduce the core loss and reduce noise. The core disc is pressed into a whole by a low-magnetic screw and an iron yoke. In order to reduce the vibration of the core during operation, shock-absorbing materials are used between the core and the reactor base for buffering.

The coil is wound with copper or aluminum wire wrapped with high-quality insulating materials. In order to prevent the generation of circulating current between multiple wires during the winding process, the wire is completely transposed. After the coil is wound, two-component epoxy resin is used to cast the coil under vacuum to ensure that there is no air gap between the turns and layers of the winding, thereby reducing partial discharge of the product.

SVG Dry-type Iron Core Line Reactor Product Reference Standards

GB/T 1094.6-2011 Power transformer Part 6: Reactor

NB/T 10289—2019 Technical specification for iron core filter reactor for high voltage reactive power compensation device

SVG Dry-type Iron Core Line Reactor Basic Ordering Parameters

System Rated Voltage

Reactor Rated Current

Reactor Rated Inductance

Performance Parameters

| Product Model |

Rated Voltage

(kV) |

Rated Current

(kVar) |

Rated inductance

(mH) |

Dimensions

(LXHXW) |

Weight

( kg) |

| CKSC-10-57.74-31.82 |

10 |

57.74 |

31.82 |

1010X1150X600 |

570 |

| CKSC-10-115.47-15.91 |

115.47 |

15.91 |

1100X1330X600 |

820 |

| CKSC-10-173.21-10.61 |

173.21 |

10.61 |

1160X1420X610 |

1040 |

| CKSC-10-230.94-7.95 |

230.94 |

7.95 |

1360X1460X650 |

1330 |

| CKSC-10-288.68-6.36 |

288.68 |

6.36 |

1430X1560X750 |

1450 |

| CKSC-10-317.54-5.78 |

317.54 |

5.78 |

1430X1500X750 |

1650 |

| CKSC-10-346.41-5.3 |

346.41 |

5.3 |

1430X1560X750 |

1720 |

| CKSC-10-461.88-3.97 |

461.88 |

3.97 |

1700X1650X850 |

1980 |

| CKSC-10-577.35-3.18 |

577.35 |

3.18 |

1790X1730X860 |

2300 |

| CKSC-10-693.82-2.65 |

693 |

2.65 |

1790X1760X900 |

2830 |